Heave and Frost Heave

The upward movement of concrete slabs caused by soil expansion, frost, or tree roots. This can create uneven surfaces that pose safety risks and lead to structural instability.

Settle, Settled, and Settlement

The downward movement of concrete slabs due to erosion, moisture changes, or improper construction. Settlement often results in voids, cracks, and an uneven foundation that compromises safety and usability.

Slope and Slope Correction

A slight slant in concrete designed for proper drainage. Over time, improper slopes can cause water pooling and damage. Adjusting these slopes through “slope correction” ensures optimal drainage and surface stability.

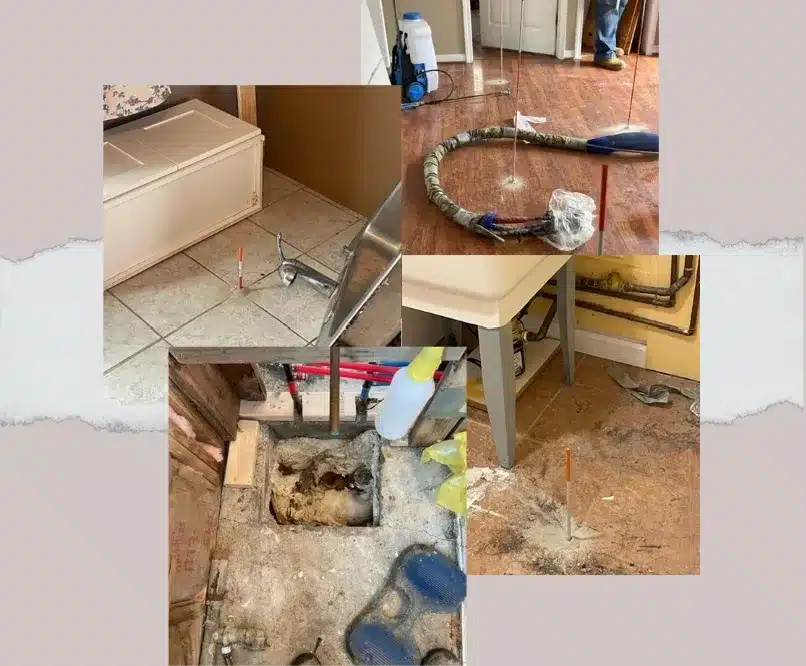

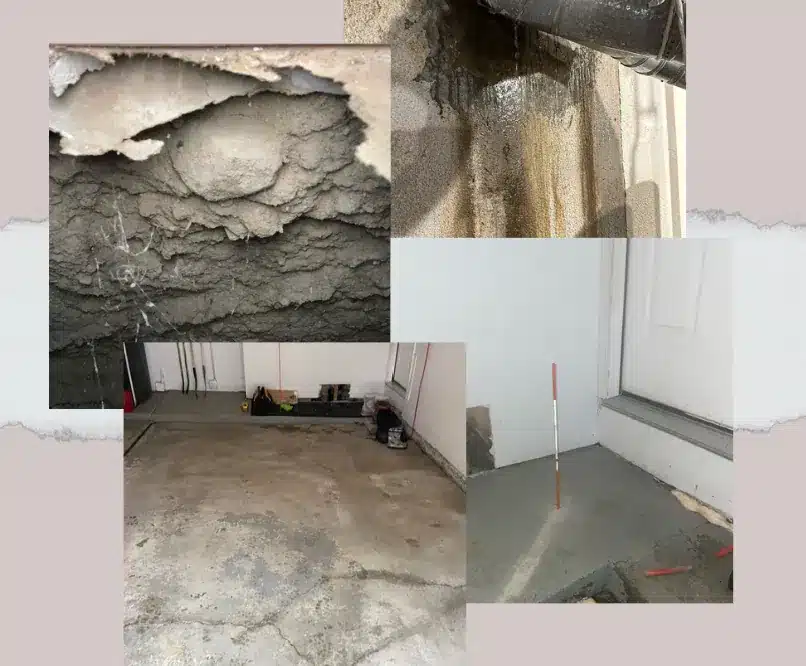

Void and Void Filling

Empty spaces beneath concrete slabs caused by soil erosion or settlement. Filling these voids with Polyurethane Foam restores support, prevents further settlement, and strengthens the foundation.

Lateral Movement

The sideways shifting of adjacent slabs, often occurring when one slab is leveled while others remain uneven. Our experts carefully assess and address lateral movement to ensure evenness and stability across all affected surfaces.

Curing and Curing Time

The time required for materials to fully harden and reach maximum strength. Traditional Mudjacking can take up to 24 hours, while Polyurethane Foam cures in just a few hours, minimizing downtime for your operations.

Sealing

Applying a protective sealant to prevent moisture penetration into concrete. Sealing is essential for extending the lifespan of your surfaces and preventing future damage.

Expansion Joint

A deliberate gap between slabs designed to allow movement due to temperature changes. Properly sealing these joints ensures durability and prevents cracks.

Mudjacking (Slabjacking)

A traditional concrete leveling method that uses a slurry mixture to lift slabs. Mudjacking often requires larger holes and can be prone to re-settlement, making it less efficient than modern solutions.

Polyjacking

A modern, reliable, and long-lasting solution for lifting and leveling concrete using Polyurethane Foam. Polyjacking addresses voids, provides superior strength, and is more cost-effective and minimally invasive compared to traditional methods.